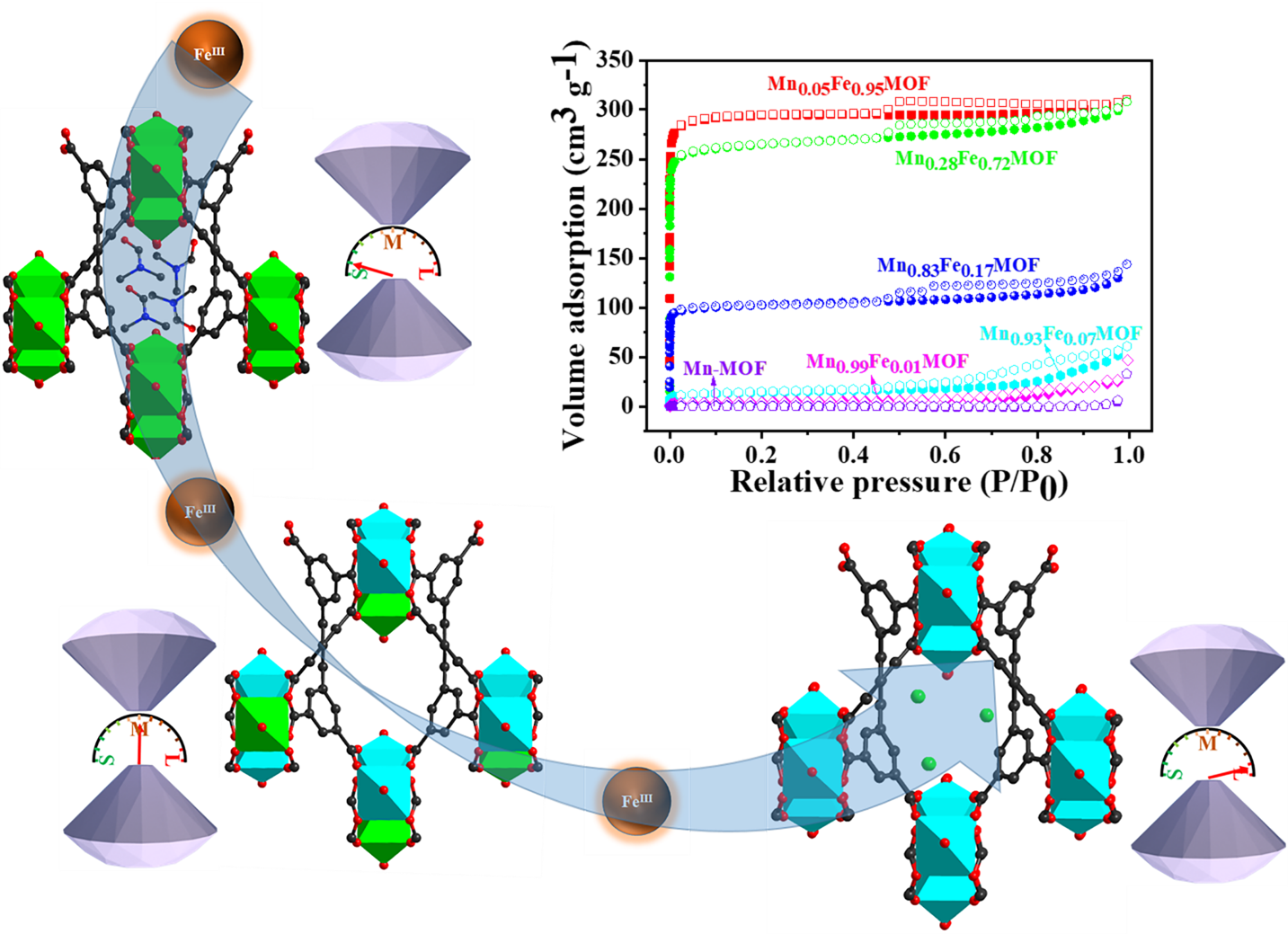

A team of HPSTAR scientists led by Dr. Zhiqiang Chen cooperated with Prof. Zhi Su from Nanjing Normal University found that the mechanical ultra-stability of MOF porous materials depends extensively on their porosity. In this particular work, compared to the amorphization of dense Mn-MOF at 0.8 GPa in a diamond anvil cell, the mechanical stability of porous Mn0.05Fe0.95-MOF has been dramatically enhanced, and the framework integrity could be maintained up to 16.5 GPa. The results are published in the journal of Inorganic Chemistry.

Metal-Organic Framework (Metal-Organic Framework) materials is a new type of crystalline materials formed by self-assembly of inorganic metal ions or metal clusters and organic ligands. It also combines the advantages of inorganic materials and organic polymers, with high specific surface area, designable structure and function, and adjustable pore size, etc., have huge application prospects in the fields of gas adsorption and separation, catalysis, chemical sensing, proton conduction, and biomedicine. However, MOF materials generally have poor stability, especially mechanical stability, which is difficult to meet industrial processing and applications. It is of great significance to prepare and synthesize MOF porous materials with high stability and reveal the relationship between the structure of MOF materials and mechanical properties.

“MOF materials presents so many amazing properties but unstable as usual. We carefully observe this new-type of ultra-stable MOF materials, which would promote most of application potentials to realities,” explained Dr. Zhiqiang Chen.

The team started from the dense Mn-MOF whose pores were filled with counterions, and introduced high valence Fe(III) into the structure through the postsynthetic modification (PSM) strategy to release the pores. With the accessible porosity of Mn1–xFex-MOF, the performance of mechanical stability was dramatically enhanced. Observation from the in situ FT-IR and XRD characterization from DAC, the framework integrity of porous Mn0.05Fe0.95-MOF could be maintained up to 16.5 GPa compared to the 0.8 GPa of dense Mn-MOF. The proton conductivity for the Mn1–xFex-MOF series was also investigated, where Mn0.93Fe0.07-MOF showed the best performance of 1.47 × 10–2 S cm–1 under 70 °C and 98% RH due to the onset of reversed charge from the anionic framework to cationic framework and the formation of the most compact hydrogen bonding net. This work provides new insights for controllable synthesis of MOF materials with specific mechanical stability.

Caption:Relationship between porous structure and mechanical stability of Mn/Fe-MOF.

金属有机框架(MOF)是由无机金属离子或金属簇与有机配体通过自组装形成的一类新型结晶材料,其具有高比表面积、结构和功能可设计、孔道尺寸可调等优点,在气体吸附与分离、催化、生物医学等领域显示出巨大的应用前景。然而,MOF材料通常稳定性较差,尤其是机械稳定性,难以满足工业加工及应用。制备合成具有高稳定性的MOF多孔材料,揭示MOF材料结构与机械性能之间的关系具有十分重要的意义。近日,北京高压科学研究中心(HPSTAR)陈志强研究员带领的研究团队报导了一种超稳定结构的MOF材料。本课题组从孔道被抗衡离子占据的实心阴离子框架Mn-MOF出发,通过后修饰合成策略向节点中引入不同量的高价态Fe(III),逐渐释放孔道。利用金刚石压机产生压力,通过原位高压红外光谱,X-射线衍射揭示了与实心母体Mn-MOF相比,具有多孔结构的Mn/Fe-MOF具有出色的机械稳定性。这项工作阐明了多孔材料机械稳定性的来源,为可控合成具有特定机械稳定性的MOF材料提供了新的见解。相关工作发表在近期的Inorganic Chemistry (DOI: 10.1021/acs.inorgchem.2c02357)上,第一作者为HPSTAR联培博士生张自由。