New study from a team of HPSTAR scientists led by Dr. Yanhao Lin, developed a novel rapid cooling assembly in a high-pressure cubic press apparatus. This improvement can significantly increase the cooling rate during quenching in high pressure-high temperature experiments, produce a free-quench-texture silicate glass. silicate glass synthesized by this assembly design can better retain the information of volatile elements such as hydrogen, carbon, and sulfur, and has important application prospects in earth and planetary science research. This work is recently published in Matter and Radiation at Extremes.

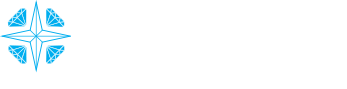

Cubic press apparatus is widely used in in high-pressure materials science and geoscience (Fig. 1). Compared with a multi-anvil press, The assembly blocks used in the Cubic press apparatus are easier to machine and assemble, compression and decompression are faster (commonly several to tens of minutes for pressing to expected chamber pressure), making these presses attractive for use in high pressure experiment. The cubic press apparatus in HPSTAR can generate pressure up to 8 GPa and temperature higher than 2000 °C at the center of the assembly block. However, conventional assembly, which prioritizes thermal insulation, limits the increasing in cooling rate. As a result, the quenched structure is formed during quenching and does not preserve information from its molten state. Synthesizing structurally homogeneous glasses in high-temperature, high-pressure experiments is a challenging technical problem. It is critical to increase the cooling rate from melt to glass at high temperatures to preserve as much of the original melt information as possible.

Fig. 1. (a) and (b) Photographs of the GY420 and GY560 cubic presses, respectively, at the HPSTAR high-pressure laboratory. (c) Photograph of six tungsten carbide (WC) anvils and a compressed assembly block from the GY560 cubic press. (d) Sketch of the pressurizing system of the cubic press, six WC anvils are driven by a compute controlled hydraulic system to generate isotropic static high pressure in the central block.

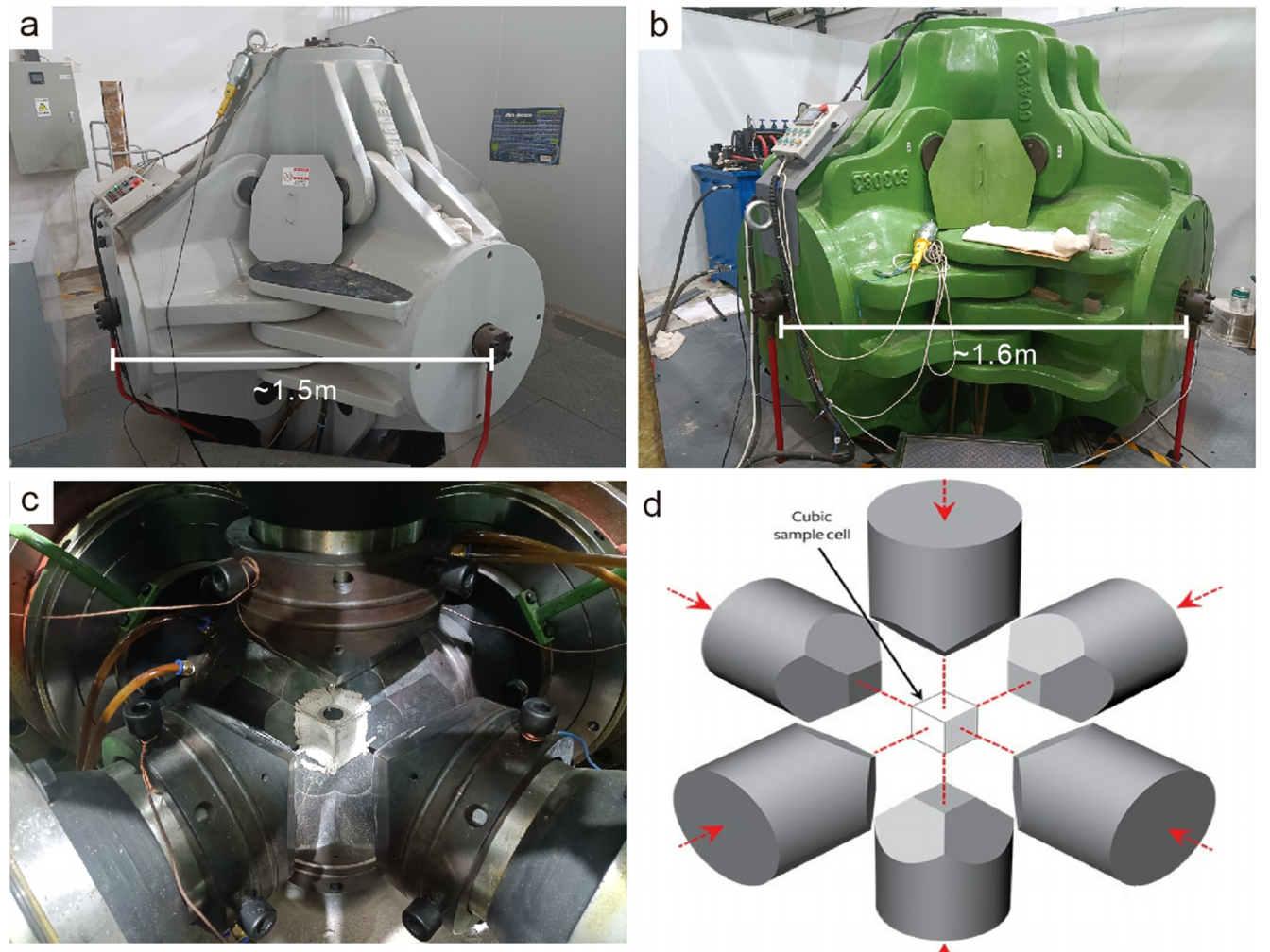

This study modified the conventional assembly by discarding the MgO sleeve between the graphite heater and the sample capsule, instead, placing the sample capsule directly in the graphite rod heater, integrating the heater and the sample capsule (Fig. 2). This new assembly offers significant advantages over the conventional assembly, including better heat preservation performance, higher heating efficiency, and higher cooling rate during quenching.

Fig. 2. Comparison of conventional assembly block(left) and rapid cooling assembly block(right).

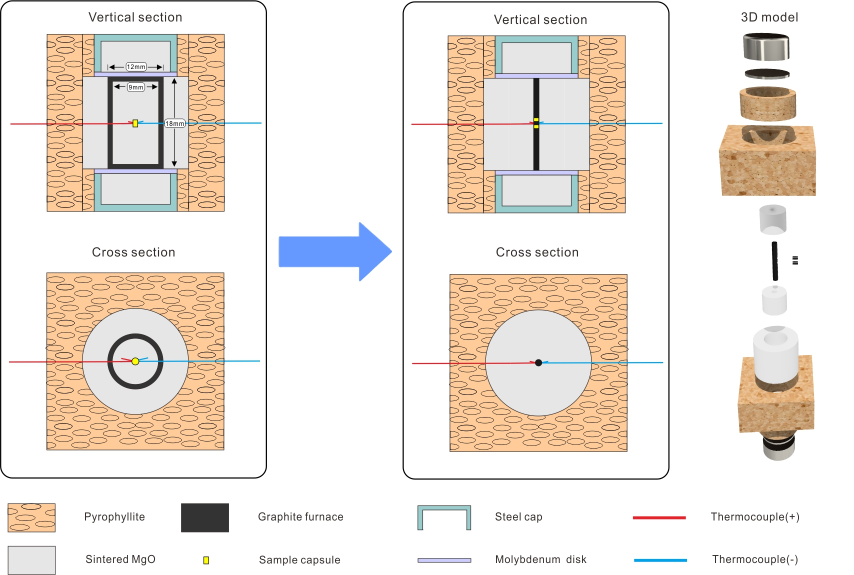

The comparison of the cooling paths of the conventional assembly and the rapid cooled assembly at a chamber pressure of 5 GPa and temperatures of 1800-1900 °C is shown in Fig.3. Cooling from 1800 °C to 1000 °C takes approximately 14 seconds using the conventional assembly, while the rapid cooled assembly takes a maximum of 1.5 seconds from 1900 °C to 1000 °C, a nearly 10-times faster in cooling rate.

Fig. 3. Comparison of cooling path between conventional assembly and rapid cooling assembly.

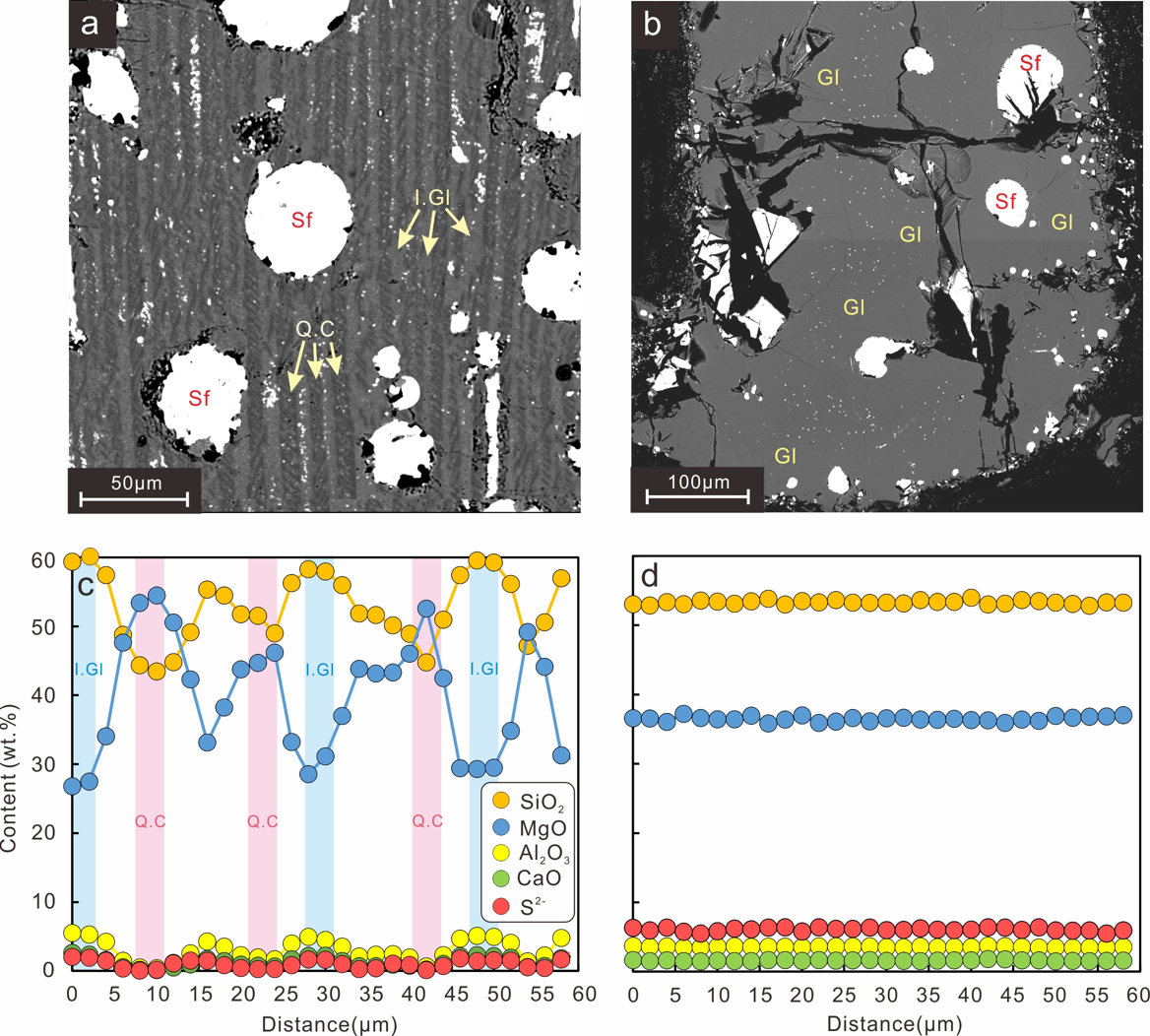

Two comparative experiments with the same starting material (FeS-added silicate material) under the same experimental conditions (5 GPa, 1950 °C) are shown in Fig. 4. The backscattered electron images show that the samples synthesized using the conventional assembly have obvious quench texture (Fig. 4a), which is due to the rapid growth of mineral crystals during cooling. For comparison, the sample synthesized using the rapid cooling assembly is rather homogeneous (Fig. 4b). This difference can be clearly seen from the compositional profiles obtained from EPMA (Fig. 4c and d). And sulfur is better preserved in the sample synthesized using rapid cooling assembly.

Fig. 4 Backscatter electron images (a, b) and composition profiles obtained from EPMA (c, d). Sf: iron sulfide; Q.C: quenched crystal; I.Gl: intergranular quenched glass; Gl: glass.

This technical improvement contributes to the understanding of the nature of silicate melts relevant to earth and planetary sciences, and has promising applications for understanding the partitioning behaviors of many volatile elements (e.g., hydrogen, carbon, and sulfur, etc.).

近日,北京高压科学研究中心(HPSTAR)的林彦蒿课题组开发了一种应用于六面顶压机的快速冷却的实验方法,该方法可以显著提升淬火时的冷却速率。利用该方法合成的无淬火结构的硅酸盐玻璃可以更好地保留氢、碳和硫等挥发性元素在高温熔融状态下的原始信息,这些原始保留下来的成分对地球与行星科学研究方面研究至关重要。相关研究成果以“A novel rapid cooling assembly design in a high-pressure cubic press apparatus”为题发表于《Matter and Radiation at Extremes》。文章的共同第一作者为北京高压科学研究中心硕士研究生吴培衍和博士后徐永江。