MAY 11, 2020

How does nanostructured silicon deform has been the subject of a long-standing debate over the past decade. Now recent research from a team of scientists led by Dr. Zhidan Zeng from HPSTAR clarifies that pressure-induced phase transitions play a key role in the plastic deformation of compressed silicon nanoparticles. Their findings are reported in Physical Review Letters (DOI: 10.1103/PhysRevLett.124.185701).

Silicon, the second most abundant element in the Earth's crust, is essential to the metal–oxide–silicon (MOS) transistors and integrated circuit (IC) chips used in most electronics, such as computers, cell phones, iPads, and cameras. Due to the scaling down of silicon IC line widths to a few nanometers, the mechanical performance of nanosized silicon is critical to the reliability of the electronics.

Silicon is well-known as a brittle material. Interestingly, nanostructured Si can display obvious plasticity in compressive mechanical loading. The origin of the plasticity has attracted great research interest. Despite various theoretical and experimental studies in the past decade, it is still subject of much debate with regard to whether the plasticity is controlled by dislocations or by phase transitions.

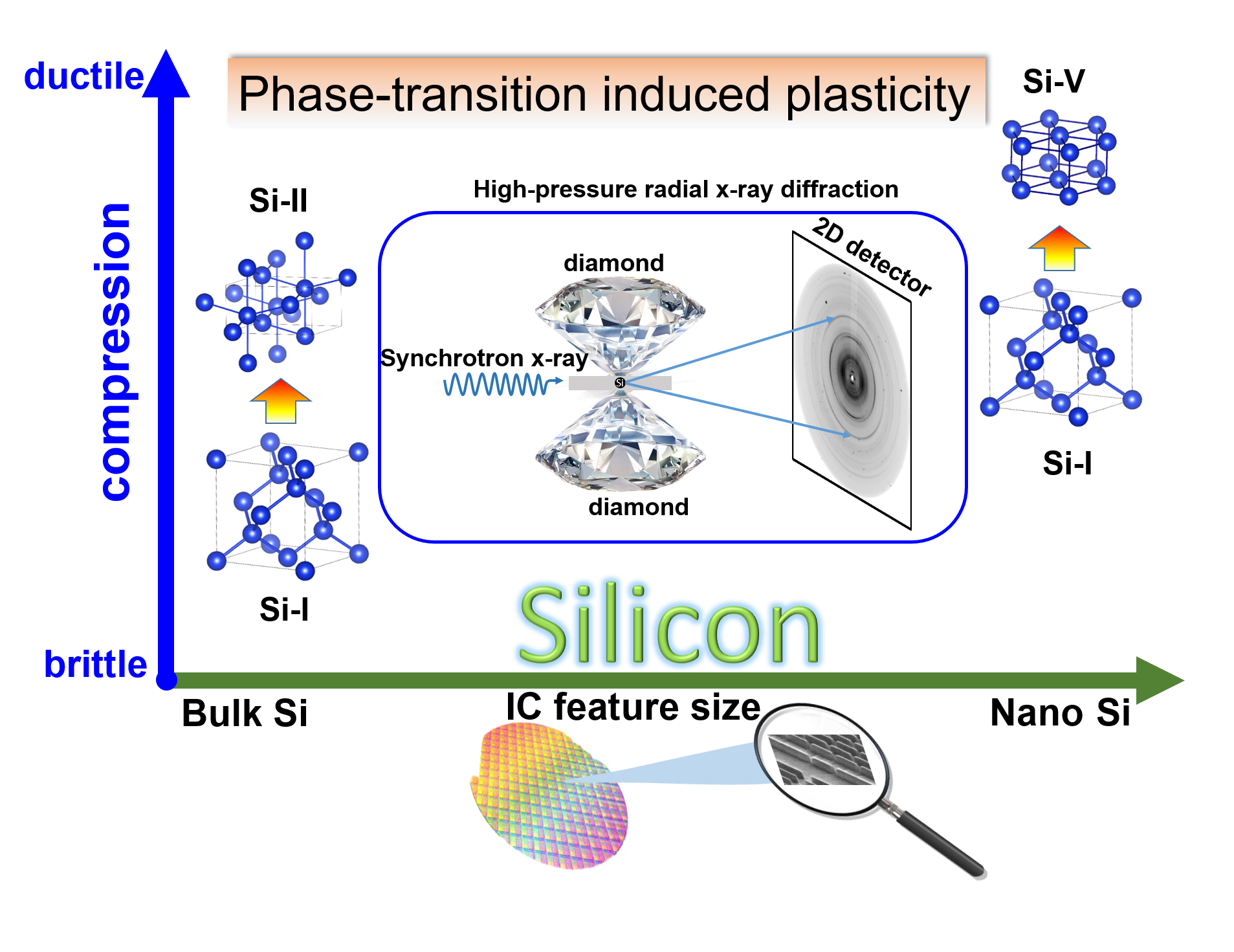

Instead of compressing individual silicon nanoparticle in a TEM as did in previous studies, Dr. Zhidan Zeng and her colleagues used a technique called in situ high-pressure radial x-ray diffraction to probe the deformation of silicon nanoparticles with average particle sizes of ~100 nm and ~9 nm.

"This method offers real-time observation of elastic and plastic deformation of materials under compression, as well as the change of their atomic structures,”explained Dr. Zhidan Zeng. "We compressed a large number of Si nanoparticles in a diamond anvil cell, so our results are based on the statistical behavior of the nanoparticles at the same experimental conditions."

They found that during compression, the plastic deformation driven by dislocation activities in the initial silicon with a diamond cubic structure (Si-I) is extremely weak and limited. In contrast, pressure-induced phase transitions could result in large plasticity due to the density difference between different phases and the subsequent substantial dislocation nucleation and motions in the ductile high-pressure phases. More interestingly, the large silicon nanoparticles (~100 nm) transform into a beta-tin phase (Si-II) in compression, while the silicon nanoparticles (~9 nm) transform into a different simple hexagonal phase (Si-V). Their further analysis and simulation also determined the active slip systems in these phases.

"Our results demonstrate that complex plasticity mechanisms are involved during compression of silicon nanoparticles as a function of particle size and stress magnitude. So we need in situ and quantitative methods to determine the real dominant factor," Zeng explained. These results can help to guide the design of various nanostructured Si-based devices and also could shed light on the deformation behavior of similar covalent nanocrystals.

Caption: A schematic diagram showing the experimental setup and the different mechanisms of plasticity in relative large and small silicon nanoparticles.

硅材料是微电子产业最重要的基础材料,也是整个现代信息社会的基石。随着集成电路的特征线宽不断降低,对硅材料的高精度加工早已从宏观尺寸跨入了纳米尺寸。因此,硅在纳米尺度的机械性能对于集成电路工业具有越来越重要的意义, 在过去十几年吸引了大量的理论和实验研究。众所周知,晶体硅是一种典型的脆性材料。有趣的是,科学家却在各种硅纳米材料中观察到了明显的压应力诱导塑性形变, 但是过去的研究对于这种塑形形变的机理却长期存在争议。最近,北京高压科学中心的研究小组利用高压原位同步辐射径向X射线衍射技术精确测定了硅纳米颗粒发生塑性形变过程中的应力、应变和原子结构变化, 从而澄清了其塑性的微观机理,相关成果以“Origin of Plasticity in Nanostructured Silicon”为题发表于近期的《物理评论快报》(DOI: 10.1103/PhysRevLett.124.185701)上。